GlorySmile Impression Material manufacturers for teeth

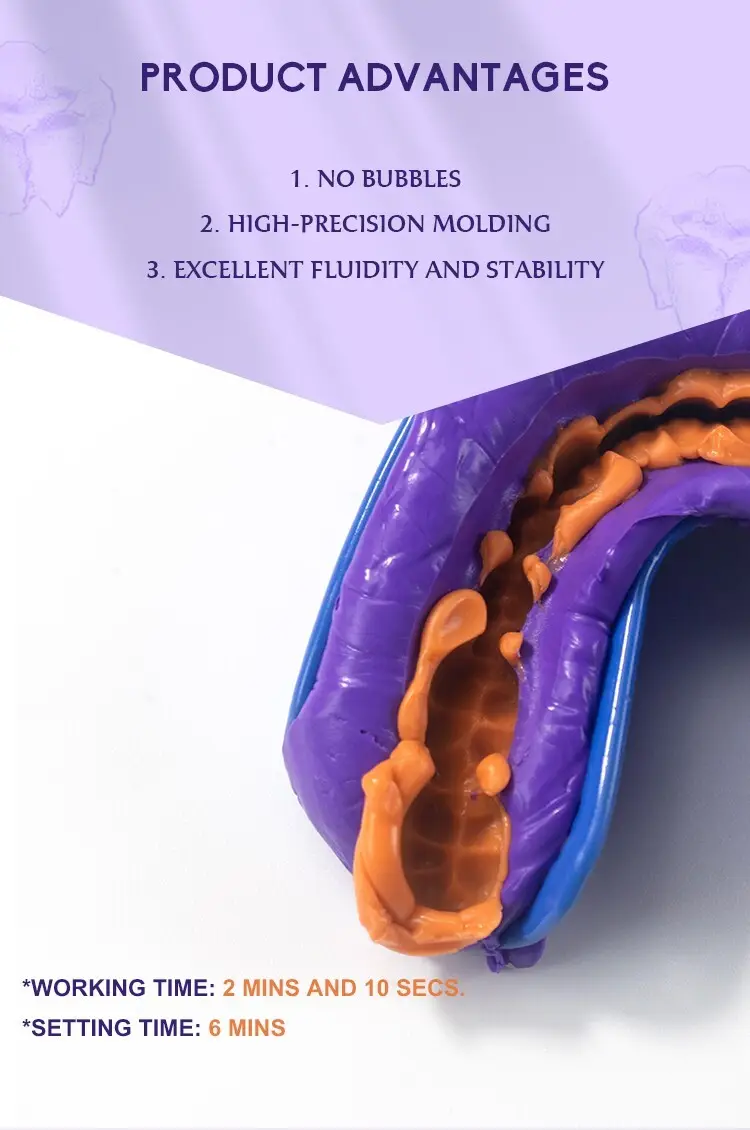

1. Impression Material The design is scientific and reasonable, and the operation is simple and convenient. The overall body is made of thickened stainless steel plate, which is hard, wear-resistant and durable.

2. Our Impression Material is high in quality and affordable, and is favored by customers, with a high return rate and repurchase rate.

3. The product is resistant to high temperature. It has been fired or sintered under very high temperature, and it has a high melting point. This product can effectively help remove the stains on the teeth surface

4. It has better contrast as the indirect light would be either absorbed in the dark saw-tooth formations or otherwise canceled out by the diffusion layers. It can penetrate tooth enamel and dentin to remove intrinsic stains from deep within the tooth

According to the number of impressions made, impression technology can be divided into primary impression method and secondary impression method.

The one-time impression method is a method to complete the work impression at one time with a suitable finished tray and alginic acid impression material or thermoplastic impression material, which saves time and is easy to operate; however, due to the shape of the alveolar ridge and the attachment position of the fringe in patients with edentulous jaws The difference is very large. The finished tray often cannot match the shape of the patient’s dental arch and alveolar ridge, and cannot guarantee proper edge extension and uniform impression material thickness. The pressure applied by the doctor to each part is also different when taking the mold. It is difficult to obtain an accurate impression model, and complete dentures made according to this often have problems such as poor retention and mucosal tenderness, resulting in failure of the repair.

Therefore, except for patients with scleroderma, extreme nausea, elderly and infirm who cannot tolerate multiple impressions, they are generally less used.

The second impression method is composed of a first impression and a final impression, and it is necessary to make two impressions in the mouth of the patient to complete the work impression. The core lies in the preparation of individual trays and the patient's active muscular function edge shaping. These two links determine whether the final impression can obtain the correct edge shape and tissue anatomy.

According to the different manufacturing methods of individual pallets, it can be divided into direct method (the finished pallet is added with impression paste to obtain the first impression, and then the working surface of the first impression is evenly scraped by 1 ~ 2 mm, and then modified into individual pallets, and then added fluidity. Better alginate impression material to obtain the final impression), indirect method (first use the finished tray with alginate impression material for proper edge shaping, then take the initial impression, pour the plaster model, and then place it on the plaster model Make individual resin trays, and then use this individual tray plus the final impression material to obtain the final impression) and the combination method (using the final impression of the direct method as the initial impression, pour the plaster model, and then make the resin individual tray on the plaster model, Then use this individual tray to add the final impression material to obtain the final impression).

Studies have shown that whether it is the initial stability, the number of compression points, or the satisfaction of testing patients on the stability and comfort of the denture, the combination method is a better choice, followed by the indirect method. Although the operation of the second impression method is cumbersome and time-consuming, but because the impression is accurate and stable, high-quality, easy to grasp, it reduces the number of follow-up visits caused by too long and too short base edges, and it has become a full mouth Specification requirements for denture impressions

Company Features

1. Committed to the production of Impression Material , Nanchang Dental Bright Technology Co., Ltd. is an advanced factory.

2. Always keeping developing the dental putty production is the core competitiveness of GlorySmile.

3. Nanchang Dental Bright Technology Co., Ltd. is committed to producing high quality and low price silicone based impression material . Get price!

QUICK LINKS

PRODUCTS

CONTACT GLORYSMILE

Contact:yvonne

Phone: +86 18979136580

E-mail:yvonne@enjoywhite.com

Makou industrial park,

Yongxiu County, Jiujiang City, Jiangxi Province, China

BETTER TOUCH BETTER BUSINESS

Contact Sales at Glorysmile.